Machining

Precision machining is a core competency of G3 Industries with both horizontal and vertical machining centers. We have sophisticated highly precision Makino Horizontal machining center with 500x500mm pallet for machining hydraulic manifold blocks to medical device components. Our 500x500mm Haas horizontal machining center help with our high volume less precision parts as well as doing substantial machining after parts are welded to help hold tighter tolerances.

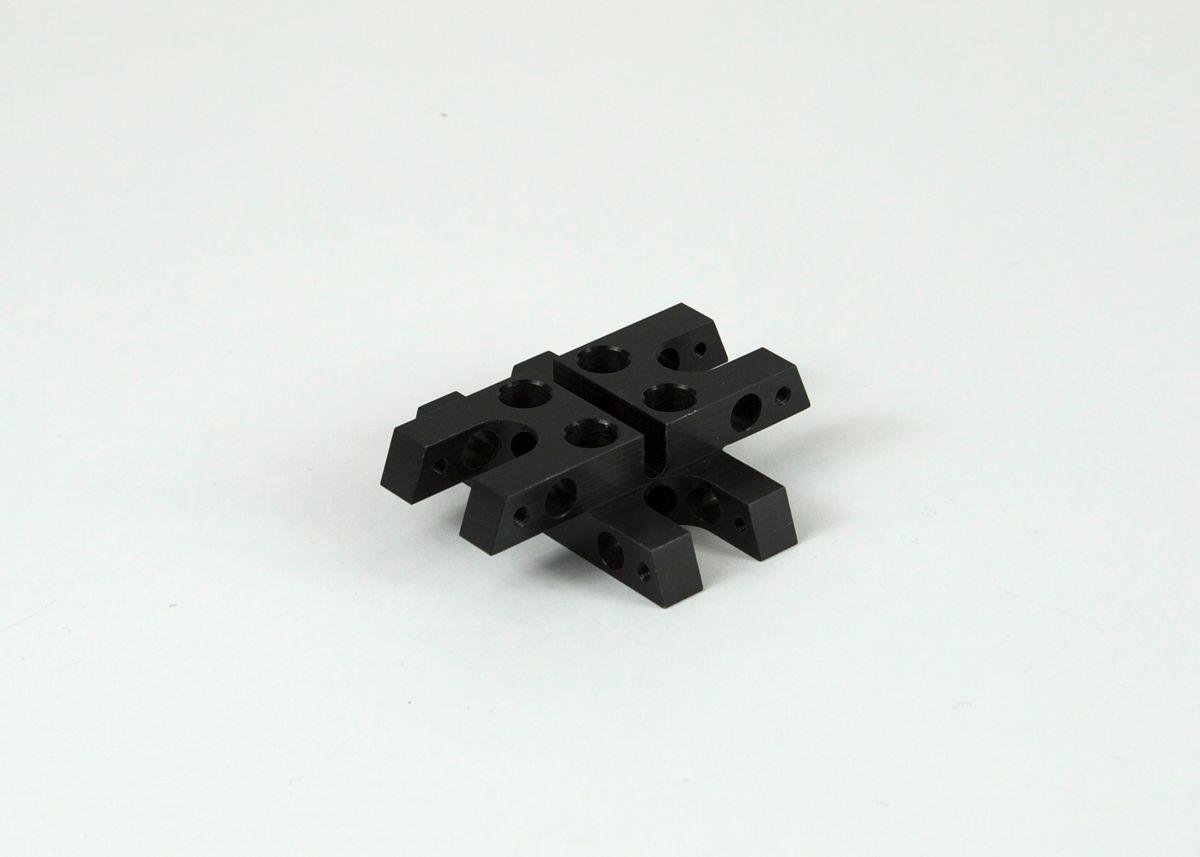

Our bushing / spacer machining center allows for three stations of work being done simultaneously to allow for faster cycle time and multiple features being put into a bushing or spacer in one machine and at the same time.

Setup and throughput are the keys to G3’s success in vertical and horizontal machining. We look to help you to save some money and enjoy the great service, excellent quality and on time delivery that brings success to G3.

Check out more of our equipment and capabilities below.

Capabilities

| Process | Capability Range |

|---|---|

| Vertical and Horizontal Machining | 500 x 500mm pallet Up to "Basketball/Football" size components |

Resource List

| Equipment | Description |

|---|---|

| CNC MACHINING CENTERS |

|

| AUTOMATIC MULTI-SPINDLE MACHINES |

|

| AUTOMATIC SINGLE-SPINDLE MACHINES |

|

| CENTERLESS GRINDERS |

|

| PRODUCTION DEBURRING MACHINES |

|

| PRESSES, RIVETERS, TUBE FORMING & SECOND OPERATION EQUIPMENT |

|